Advancing Healthcare Device Design

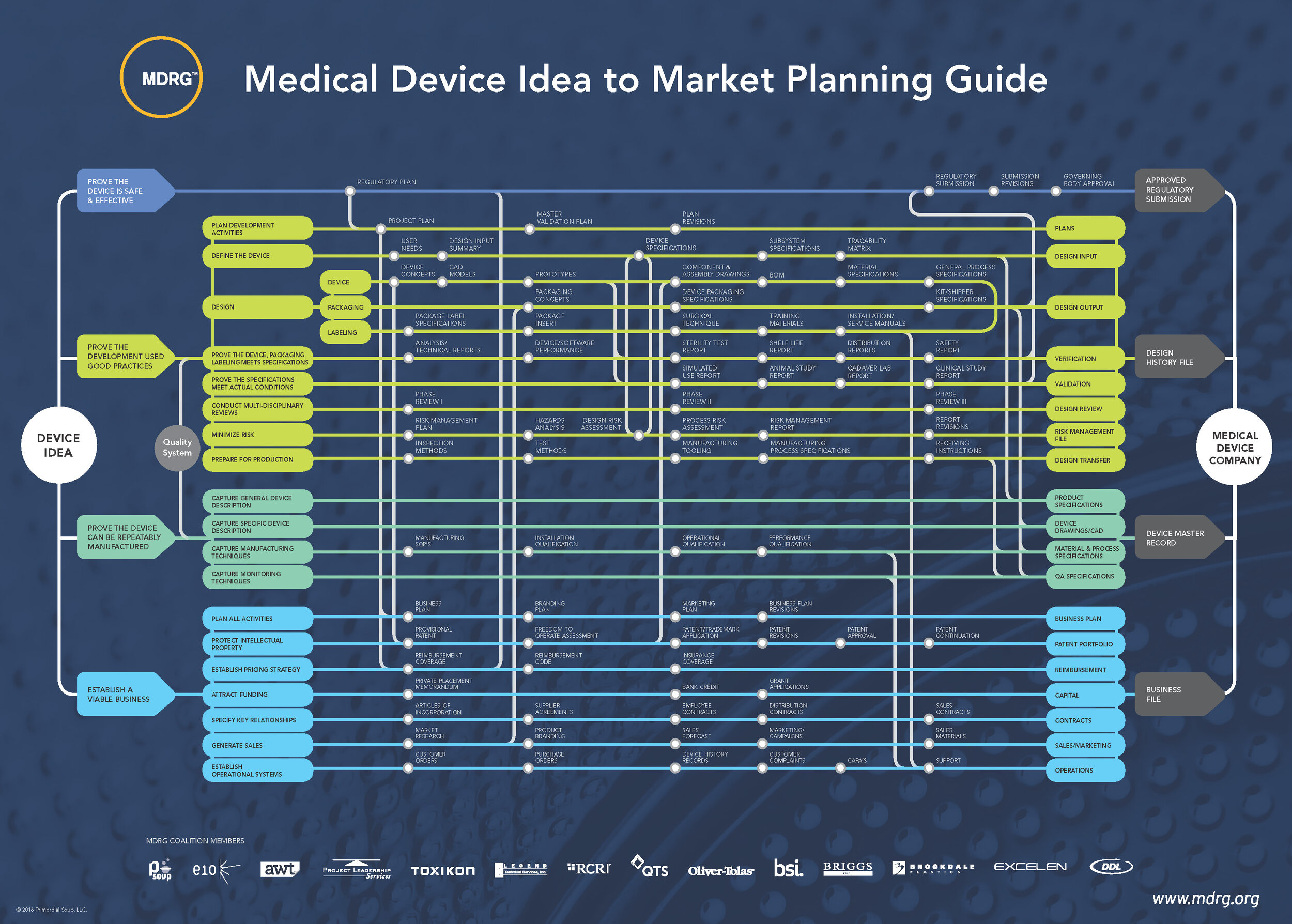

Because we're mechanical engineering centric,

clients leverage our experience on a range of interesting projects.

Lean Organization

Working with us, you won’t spend a lot of time with unnecessary meetings or paperwork.

Perfect Mix Of Industrial Design & Mechanical Engineering

You’ll work with a results driven, dedicated creative team who gets things done.